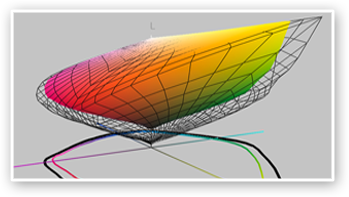

Color Gamut has become one of those over used terms in the world of color printing which deserves a bit of time to explain. Which inkjet paper has the widest or greatest color gamut? Which paper has the darkest, richest black? Which paper is going to most accurately represent what is seen on my computer screen? These are all great questions and represent some of the mysteries and myths of inkjet printing

Paper profiles are the critical point of failure in the printing process! If your paper profile isn't right, your print won't be either. If you want to print knowing that you are printing the best image, custom profiles are for you.

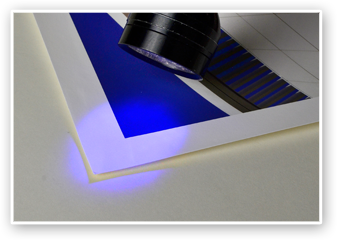

Many customers ask us, "What paper is going to give me the brightest white?" The easy answer is "The paper that contains the most optical brighteners." Since we don't use white ink in our inkjet printers, the brightest point in our images is going to be determined by the white point of the paper we use. This has a definite effect on how our images look.

Part of taking control of your digital images is recognizing what the nature of the media is you are printing on, and how it affects your presentation. Optical Brighteners, also known as OBAs, are a hot button topic amongst digital printing professionals.

One of the more commonly asked questions in digital printing is, "What is the archivability of the paper I am using?" How long your prints will last depends on how you handle, present and display them more than any inherent archival properties of the paper itself.

Exploring different inkjet papers can make digital printing not only fun, but an area of exploration unlike anything we have ever experienced. It's an amazing experience to print and see the same image on different types of textured inkjet media.

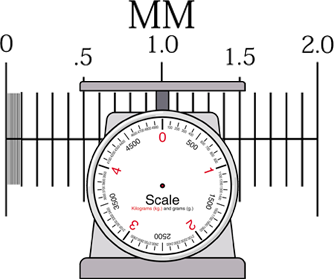

A common misconception is that the letters GSM on boxes of inkjet paper refer to the thickness of the paper. This of course is not true. GSM or g/m2 stands for Grams per Square Meter and is a measure of weight not thickness. But asking for a 310 gsm thick paper is the wrong question...

Following is a relatively simple three step method for making digital negatives. With some of the more forgiving processes like gum and casein, only the first two steps may be needed.

Awagami's Kozo paper is double layered; the top layer is made of "Kozo" - durable plant fibers made from the Kozo plant. The bottom layer is made from wood pulp. The process for separating the top layer of Kozo from the wood pulp backing requires a bit of practice and patience but it is well worth it.